Trimble tested the speed and accuracy of novice, intermediate and expert operators using conventional and machine guided excavators, and found the latter led to big improvements across the board.

The latest quarterly Commercial Construction Index (CCI) report from the US Chamber of Commerce shows construction companies still struggling to find skilled workers.Â

83% respondents reported moderate to high difficulty in finding them, with 87% expressing a moderate to high degree of concern about workers having adequate skill levels. 83% of respondents had asked their skilled crew members to do more work, and 71% reported struggling to meet schedule requirements.

One way to tackle the shortage of skilled labour is to use supporting technology used on the job site. While adoption has been steady over the years, many construction professionals are still hesitant to invest in technology, unsure of the benefit-to-cost value. Overall, the CCI report states, nearly half of the contractors plan to not raise spending on tools and equipment in the next quarter.

Integrated grade control technology

Over the years, positioning-technology innovators and construction equipment manufacturers have integrated grade control technology on excavators, dozers, motor graders, skid-steers, milling machines, pavers and other earthmoving equipment. Trimble wanted to test whether this technology in earthmoving equipment could raise productivity.

So, we carried out a study to compare the performance of operators of varying skills – novice, intermediate, and expert – using a) conventional, b) guidance-only and c) fully machine guided excavators. The results were stark.Â

Methodology

Researchers asked 16 operators to perform the simple but common task of digging a 1m wide x 15m long by 0.5m deep trench to an accuracy of plus/minus 3cm using Komatsu PC228-10 and Hyundai HX220-L excavators.

Before each trial, participants were given the same warm-up period to familiarise themselves with the machine (e.g., practicing with the controls, digging in a test trench, interacting with the Trimble Earthworks interface).

During the first trial, participants used conventional excavation methods-no design or external grade control. At intervals of the operator’s choosing, the moderator checked excavated elevations using an SPS986 receiver, providing indications of the required cut and fill values at certain locations. The trench was considered complete when a participant indicated that they had finished excavating.

In the second trial, participants excavated the same sized trench using the guidance only function of Trimble Earthworks Grade Control Platform. Participants had access to the trench design and Earthworks interface but did not have any automatic machine control.

During the last trial, participants excavated using Trimble Earthworks’ “Automatics” functionality. The machine control system includes a 2D guidance system that will dig to design elevation automatically. The operator controls the stick, and Trimble Earthworks controls the boom and bucket to stay on grade. This essentially automates the excavator operation.

As with trials 1 and 2, when complete, the moderator took measurements with a Trimble TSC7 Controller and the Trimble SPS986 GNSS Smart Antenna along the length of the trench to verify the accuracy of the excavation according to the design.

Automatics made novices 62% faster

All operators met the tolerance requirements in all three trials. However, on average, novice operators were almost 50% faster with guidance-only than conventional methods and over 62% faster with automatics as compared to conventional methods.

The study indicates that while a novice operator does not have the experience to handle a machine with the same skill as an experienced operator, guidance, and particularly automatics, can significantly improve their ability to get jobs done faster with accuracy.

Intermediates become expert

Intermediate operators were on average around 27% faster with guidance-only than conventional methods and over 38% faster with automatics as compared to conventional methods. Also, of note, intermediate operators who used automatics were comparable to expert users in guidance only (6:41 to 6:03).

Experts got even faster

It’s no surprise that expert operators performed very well in all test scenarios. They were the fastest and most accurate. But even these expert operators, who on average completed the project in 9 minutes and 56 seconds with conventional methods; cut their time almost in half (5:25) using the Automatics function.

The study numbers indicate that guidance – and particularly automatics capabilities – make a very good operator better and enable less skilled operators to perform close to intermediate and expert operators with comparable accuracy. Adding machine guidance to the technology portfolio, adds to a company’s flexibility and agility, opening up the possibility of empowering less skilled workers to step up their machine control game.

Read the full Global Construction Review article HERE.

Potter’s Excavations Ensures Millimetre Accuracy

Sitech’s Kevin Lawler was recently out on a Potter Excavations jobsite outside Balranald where Potter’s is using Trimble grade control together with a Trimble Universal Total Station (UTS) kit, allowing their machines to complete work to millimetre accuracy, quickly and efficiently.

Kev was asked to perform a calibration and 3D position verification of some machines on their job to ensure this continued top-notch accuracy.

Providing the highest possible degree of accuracy for construction site positioning, stakeout, measurement and machine control, you can use Trimble UTS for:

- Tasks where the accuracy requirements are very tight: 3 millimetres (0.01 feet)

- High precision machine control and guidance

- Smaller construction sites, or combined with GNSS on larger sites

- Measuring dangerous or inaccessible locations

- Reflectorless measurement of stockpiles, rock faces, cuttings and structures

- Tunnel measurement.

Trimble and Microsoft Partner to Drive Digital Transformation Across Industries

Trimble and Microsoft have announced a strategic partnership to advance technology adoption and accelerate the digital transformation of the construction, agriculture and transportation industries.

The two companies will work together to develop an industry cloud to enable construction organizations to harness the value of digital construction data across the project lifecycle from design, build and operate.

The construction process is fragmented, which can result in lost productivity, rework and a lack of transparency.

The ability to link technologies, tasks, processes and multiple stakeholders—such as general contractors, subcontractors, designers, engineers and owners—across the construction project workflow can transform and significantly improve productivity, quality, safety, transparency and sustainability.

This partnership expands Trimble and Microsoft’s existing relationship to combine the Microsoft cloud with Trimble’s construction solutions and industry domain knowledge.

The companies will deliver the Trimble Construction Cloud in 2022.

“Trimble and Microsoft will create a powerful partnership to advance technology adoption in the construction industry. Using Microsoft technologies, Trimble will be able to more rapidly develop a construction cloud to connect stakeholders and workflows throughout the industry,” said Bryn Fosburgh, senior VP, Trimble.

“We are building on our combined success to help construction companies use digital data to improve productivity, reduce costs, increase collaboration and create agility.”

“Industry customers are accelerating deployment of cloud-based services and solutions to facilitate better decision making based on data-driven insights, gain efficiencies, reduce costs and engage customers in new ways,” said Casey McGee, VP Global ISV partners, Microsoft.

“We are excited about our enhanced collaboration with Trimble as it will help customers, across industries, evolve their cloud strategies and realize business transformation.”

Read the full release HERE.

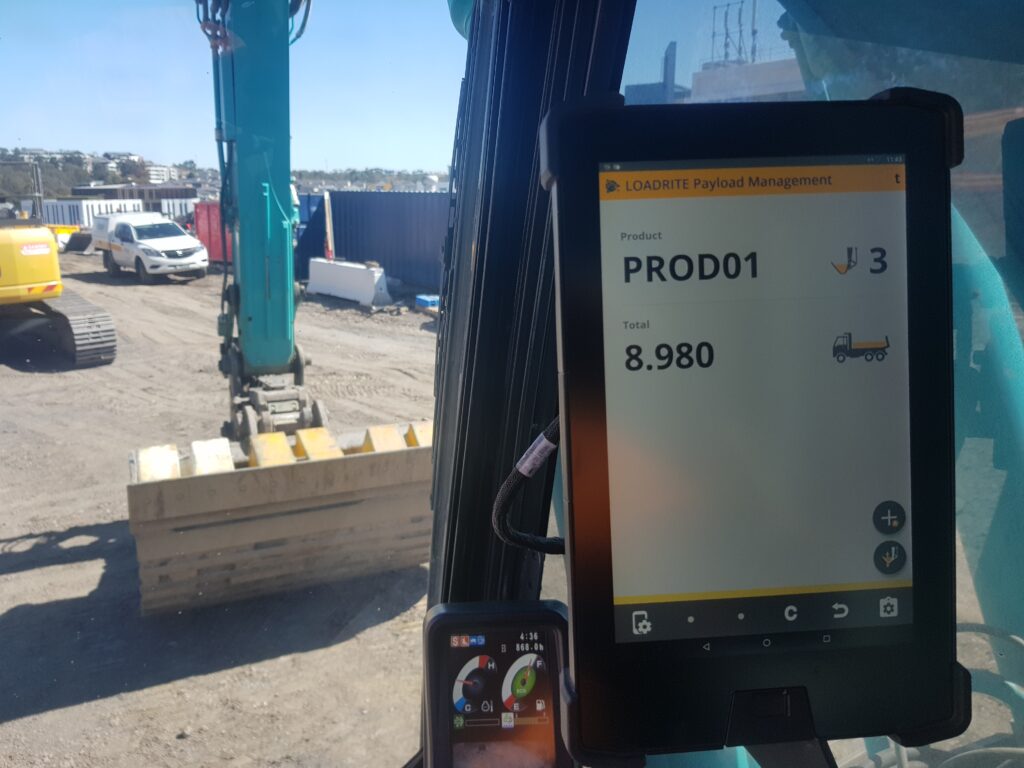

D Group 3D Dual GNSS Trimble Earthworks System with Integrated LOADRITE Payload Management Install

“Wherever you go, no matter what the weather, always bring your own sunshine,” a wise man once said. And that’s exactly what SITECH Solutions’ Kevin Lawler did recently when he visited D Group in ACT and fitted their Volvo ECR235 with 3D Dual GNSS Trimble Earthworks System complete with LOADRITE Payload Management.

Straight from the fit out to working on a residential subdivision and to now currently working on a commercial development site in the ACT, the Volvo ECR235 is well and truly working to maximum efficiency thanks to the fit out by Kev.

LOADRITE Payload Management for Trimble Earthworks Grade Control Platform allows you to maximize your machine control investment with integrated payload management. You can track how much weight is in each bucket and how much weight has been added to a cycle.

Increase the versatility and productivity of your machine – with Trimble LOADRITE Payload Management for Trimble Earthworks you can leverage your existing Trimble Earthworks machine control investment to load more in less time.

ABOUT D GROUP

Founded in 1994, D Group has grown from a local plumbing company into one of Canberra’s leading civil, hydraulics and construction management firms.

D Group has been involved with some of the most notable and prestigious projects throughout ACT, with a track record for providing the full spectrum of civil engineering, sub-structure and external works packages to industrial, commercial and retail schemes.

Trimble: Giving Construction Machinery a Brain

“If you’re not using technology in five years, you’re not going to be able to be competitive,” says Scott Crozier, vice president, Trimble Civil Engineering and Construction, on the subject of technology in the construction industry.

Crozier accepts that in the beginning it was the larger contractors that were the ‘innovators’ and adopted construction technology, but says that the tide is now beginning to turn and increasing amounts of smaller contractors are embracing it.

“We see a big gap at the smaller contractor level, between those that don’t believe in it and those that realise they are not going to be in business if they don’t invest in it.”

Scott says that these firms that have invested in construction technology have seen an increase in efficiency and are now looking for what the next gains are.

“Those that have been using digital construction tools for a period of time, now they’re onto data-driven and analytics to help them help find additional efficiencies. You need those digital tools to be able to get the data. Now they’re running analysis on that data to find out areas where they could improve, help their future estimates and look for efficiencies to be gained in certain tasks and coordination of tasks that they’re working on.”

Read the full KHL Group interview HERE.

Is Machine Control Right for You? 5 Considerations to Help You Evaluate

No contractor is too small for technology. Smaller contractors actually need it more than a larger contractor, because they need to get more done with a smaller team. Most contractors see a return on investment in six to nine months. The most common feedback is “Why didn’t I do this sooner?”

Here are 5 considerations if you’re thinking about implementing machine control technology to grow your business.

ONE: What are your Pain Points?

Examining the issues that are currently draining profits or hampering business growth often helps to identify a way for technology to lessen the burden.

TWO: Consider Cost Savings, Not Just the Expense

While you are going to invest more for equipment using 2D or 3D machine control, you can also rake in some savings.

THREE: Machine Control is more Flexible than you Might Expect

Dozers, excavators and graders can all share much of the same technology hardware. This can increase overall usage.

FOUR: Do you have a Technology Champion?

One of the keys to success in technology adoption is having the right person within your company who is going to be a champion for the technology. Plus a training plan.

FIVE: Ask for a Demo

One of the best ways to observe the technology benefits is through a demo. When contractors see the results for themselves on the job, they know it’s going to do great things for them.

Contact us for a demo today. Read the full @conexpoconagg article HERE.

With thanks to @SITECHSouth and Eric “EJ” Herron @dig_it_digital_gps.

Biletics’ Cat 310 Mini Excavatior Unstoppable with Trimble 3D

Already delivering power and performance in a mini size that allows it to work in a wide range of applications, Biletics Excavations’ newly fitted out Cat 310 mini excavator will now be unstoppable.

SITECH Solutions’ Pete Huy recently installed a Trimble 3D Earthworks complete with LOADRITE Payload Management on Biletics’ Cat which has been working on the Albion Park Airport upgrade project for Cleary Bros.

LOADRITE Payload Management for Trimble Earthworks Grade Control Platform allows you to maximize your machine control investment with integrated payload management. You can track how much weight is in each bucket and how much weight has been added to a cycle.

Increase the versatility and productivity of your machine – with Trimble LOADRITE Payload Management for Trimble Earthworks you can leverage your existing Trimble Earthworks machine control investment to load more in less time.

ABOUT BILETICS EXCAVATIONS

Biletics Excavations is an expert demolition and excavation business, providing professional and reliable service around the Illawarra area. Biletics is experienced in all aspects of excavation, including general excavation, trenching, driveways, hydraulic rock breaking and general site cleanup.

“Best System Set Up I’ve Ever Seen” Trimble 3D Earthworks for Northpipe Constructions

“It’s the best system set up that I’ve seen,” comes the verdict from SITECH Solutions’ Matt Leonard after upgrading a 2D Cat D5K2 to a full 3D Trimble Earthworks system for Northpipe Constructions.

As he watches the machine moving in full automatics at high speed whilst rotating the blade back and forth and maintaining grade perfectly, Matt says it’s straight up the most impressive machine that he’s even laid eyes on.

“The speed at which the Trimble GS520 sensors can receive the data and calculate it all compared to the older systems is unbelievable,” says Matt.

When asked what his thoughts were on the new system, Northpipe’s operator keeps it short, sweet and to the point- “It’s bloody unreal,” he says.

The Cat has been set to work on a new housing estate development project in Valla Beach, Nambucca Heads and Northpipe Constructions is stoked with the results the machine is achieving.

It’s their first Trimble system and we’re pretty confident it won’t be the last.

ABOUT NORTHPIPE CONSTRUCTIONS

Northpipe Constructions has over 15 years of extensive experience in performing bulk earthworks, constructing roads in all surfacing types, excavation, drainage & culverts, kerb & gutter, bridgework associated abutments, pavement stabilisation, traffic management and road signage/furniture.

Northpipe has completed a huge number of projects for small and large residential sites and industrial projects for government departments, major developments and private clients.

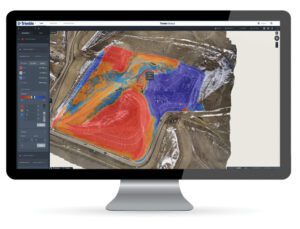

Trimble InsightsHQ – Remote, Integrated Reporting

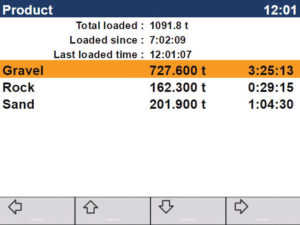

Trimble’s acquisition of Loadrite opened the company up to possibilities in the aggregates industry, including technological integration.

Trimble also gained ownership of Loadrite’s scale technology, including the company’s loader scales, excavator scales and belt scales.

The scales can determine the exact weight of materials in or on the equipment, as well as track the operational activity of the equipment.

To coordinate with these scales, Trimble began to integrate its current technological capabilities with the aggregate scales. The company came up with Insight HQ, a browser-based platform where operators can view the data from their equipment.

The company integrated the scales with Insight HQ so the scales can send information to the Insight database.

“We’re bringing an improved version of the existing technology,” said Johan Smet, GM of the quarry division for Trimble Loadrite. “Insight HQ is a consolidated platform taking a lot of our reporting capabilities from different systems to one platform.”

Insight HQ uses the Cloud to consolidate the equipment info from each scale. Thus, operators at different locations can access information & determine the progress at a site.

“We’re showing improved reporting capabilities,” said Smet. “We’re bringing improved versions of the existing scales from Loadrite and a whole other set of existing Trimble technologies.”

Read the full pitandquarry.com article here.

Behind the Scenes: Trimble Earthworks install for JBJ Civil

Behind the scenes with Jye Gregory, going the extra mile, working well into the night to get JBJ Civil’s 140M3 up and running with a Trimble Earthworks installation.

Fundex Equipment to Offer Trimble Groundworks Machine Control System for Piling Rig Guidance

Trimble and Fundex Equipment have announced the availability of the Trimble® Groundworks Machine Control System for piling machine guidance as an option on Fundex Equipment foundation machines.

Trimble Groundworks helps construction companies accelerate piling operations with stakeless workflows, 3D guidance and safer sites using Fundex Piling Machines.

Trimble Groundworks is a 3D machine control system for piling rigs that improves efficiency and reduces downtime with stakeless navigation, monitoring productivity and quality, and managing design data from office to field. Trimble Groundworks helps optimize productivity, reduce driving time per pile for piling rigs and enables operations to work day or night and under almost any weather conditions. Part of the Trimble Connected Site® portfolio, Trimble Groundworks is a connected solution between office and field workflows.

“Trimble Groundworks increases the value of our equipment for our customers,” said Anton Hectors, manager E-systems, Fundex Equipment. “Thanks to integration of the machine control system with our Fundex Equipment foundation machines, operators can drive piles more efficiently and with higher quality.”

“Both Trimble and Fundex have a long history of providing innovative solutions for piling operations,” said Kevin Garcia, general manager of Trimble’s Civil Construction Solutions Division. “Trimble Groundworks technology on Fundex Equipment Foundation machines will enable our customers to maximize piling productivity and safety to new levels, with a reliable and accurate workflow.”

3D Guidance

Trimble Groundworks provides accurate piling depth, direction and drill hole calculation, enabling operators to drill exactly to the required depth. The Auto-Stop feature eliminates over/under drilling and reduces machine wear and tear.

Safer Piling Workflows

When Groundworks is used with Trimble Business Center software, administrators can set avoidance zones in the design file. This can alert the operator of areas to reduce blind spots. In addition, Groundworks reduces the need for surveyors and support staff to be near the machine, making worksites safer.

Layout and Record As-Built Data

Groundworks allows for operators to create an in-field stakeless piling design and export layout and as-built reports. These reports meet the International Rock Excavation Data Exchange Standard (IREDES) for workflows for machine and software interoperability.

About Fundex Equipment

Fundex Equipment B.V. designs, produces and supplies multifunctional foundation machines all over the world. More than 60 years of experience in the field of various foundation techniques is the basis for the development of all their products. Fundex Equipment offers a wide range of foundation machines for various foundation techniques in the civil market with auxiliary equipment such as rotary heads, casing clamps, ring vibrators and hydraulic power packs.

Fundex Equipment to Offer Trimble Groundworks Machine Control System for Piling Rig GuidanceRead the full announcement on prnewswire.com

Trimble’s vision of a far more efficient future

Trimble is offering a future with more efficient, optimised construction operations for faster project delivery.

The global pandemic has had a huge impact all around the globe, with the threat to human health affecting all industries and all activities. However, the latest technology is offering solutions and helping firms to adopt systems that are already available.

This is certainly becoming apparent in the construction sector, where contractors and technology suppliers are meeting the many challenges posed by the pandemic.

Construction activity was halted initially by the pandemic in many areas but then was able to commence again by following new practices, with technology playing a key role.

Pete Large is in charge of civil construction field solutions at Trimble and he believes that the pandemic has certainly affected the adoption of technology in construction.

He commented, “In the civil engineering sector we’re definitely seeing some trends there.”

Machine control systems are offering benefits for social distancing measures on construction sites

Fast data transfer between machines and site office can be achieved using technology, with contractors increasing their use of such systems due to the pandemic

New tools allow firms to monitor operations and carry out remote surveying to enable social distancing on the modern construction site

Plus much more. Read the full World Highways article HERE.

“All these things we’ve been forced to do because of the pandemic will stick.”

Introducing the Trimble GuidEx Machine Guidance System

Trimble has introduced theTrimble GuidEx Machine Guidance System, an advanced machine navigation solution intended to quickly and efficiently guide machines along route corridors or to specific target areas, while providing local awareness using customer-provided mapping or engineering data to create exclusion and inclusion zones.

Trimble GuidEx uses an integrated GNSS and inertial navigation system (INS) to compute a virtual reference point and precise heading, pitch and roll.

Users can install the Trimble GuidEx system on anything from utility terrain vehicles (UTVs) to heavy equipment, on- or off-road.

Trimble GuidEx provides streamlined design-stakeout navigation that eliminates the need for advance survey stakeout operations. This enables machine operators to navigate to an exact point without stakes or surveyors, such as for core-sampling operations.

Corridor navigation allows users to efficiently complete a range of tasks including clearing paths for access routes and plowing snow. With comprehensive local machine data-logging, contractors can capture a range of data including position, time and speed.

“Trimble GuidEx was built to meet the needs of natural resource exploration activities, but can be used for many other applications,” said Scott Crozier, vice president of Trimble Civil Construction. “This system improves productivity and awareness with easy, efficient, task-specific navigation.”

SOLAR PROJECT: Trimble Machine guidance accurately installs 110,000 ground screws with a 50% program acceleration

Contractor TerraSmart combines its innovative solar panel foundation methods with Trimble machine guidance drill systems to accurately install 110,000 ground screws with a 50% program acceleration.

Project Highlights:

– Greater than 50% acceleration in completing each solar panel block, compared to traditional stake and survey methods

– Met hole and ground screw tolerances of +/- 2 centimetres

– Placed approximately 110,000 ground screws with minimal staking

– Saved upwards of $250,000 and significant time in survey costs – eliminated the need for a team of full-time surveyors

Solar panels require a strong, durable foundation; contractors have often used piles for solar panel foundations. However, when the soil is extremely rocky, dense and full of caliche, driving piles into the ground becomes a significant challenge.

Following discussions with SITECH, the TerraSmart team made the decision to equip five drill rigs with the full 3D Trimble DPS900 Drilling System.

After just four months of using the ground screw method and the Trimble DPS900 systems on its rigs, the TerraSmart team accurately drilled more than 62,000 holes and completed the rock drilling portion of blocks five and six – nearly a 50% acceleration in completing each block compared to using traditional methods. The team has also improved the accuracy of the rock drills over time, fine tuning the entire system to work with ground conditions, allowing them to maintain holes within ½ in (12.7 millimetre) tolerance.

James Meyer, Survey Lead for TerraSmart explained that another piece of Trimble technology has provided them with the ability to satisfy another one of the general contractor’s specifications. On this particular project, the owner requires the panels to follow the topography of the land; essentially mirroring the undulation and elevation changes of the terrain.

Using Trimble DPS900 and SPS930 Universal Total Stations, TerraSmart developed an algorithm to meet project specifications. TerraSmart implemented this unique process with the help of Trimble and Atlas Copco.

With Trimble SPS930 Universal Robotic Total Station and the algorithm that takes into account the known ground elevations, the team set the mounting legs to match the elevation change of the ground, translating into the solar panels mounted on top of legs flowing with the grade of the land. Using this system, TerraSmart ground crews were able to adhere to the height, placement, and 1% angle break between leg tolerances required by the general contractor.

ABOUT TERRASMART

TerraSmart leads North America in solar ground mount racking design, engineering, and manufacturing. The company has more than 30 years of experience in structural engineering and steel fabrication. Headquartered in Estero, Florida, TerraSmart delivers the most technologically advanced solar ground mount racking solutions in the industry.

Trimble Announces Earthworks Upgrade for Soil Compactors

Wider Range of Machine Types Now Available on the Trimble Earthworks Platform

The Trimble Earthworks Grade Control Platform version 2.4 offers support for soil compactors.

Trimble Earthworks for soil compactors is a GNSS-based, 3D compaction control solution designed to make soil compaction more accurate, faster and easier. Operators will experience the same intuitive, easy-to-use Trimble Earthworks software interface currently available for excavators, dozers and motor graders for improved productivity.

Compaction Control.

Trimble Earthworks for soil compactors enables contractors to accurately control the compaction process, while reducing unnecessary passes that can result in over compaction. The platform makes the overall compaction process more efficient, with a higher level of accuracy and less rework. With soil compaction part of the extensible Trimble Earthworks platform, contractors can take advantage of shorter training times, less downtime and increased remote operator support in the field as well as benefiting from ongoing platform developments.

“Trimble Earthworks for soil compactors is easy to learn and more accessible for many different types of users because it leverages the intuitive Trimble machine-control interface and applies it to soil compactors,” said Scott Crozier, vice president of Trimble Civil Construction. “Adding this new machine type to the Trimble Earthworks platform gives contractors the ability to more easily manage their mixed fleets, train operators and manage jobsite data.”

Improvements in material/surface lifts and layer management allow for more accurate data and easier data management. Office-to-field connectivity enables efficient communication and data transferring across the project. In the field and office, contractors can easily interpret the valuable productivity data collected from the machine, such as work previously completed versus work completed that day.

Read the full GPSWorld.com article.

Trimble introduces simplified Siteworks software

Trimble Siteworks SE Software is intended for users who do not require a full feature set.

The newly launched Trimble Siteworks SE Starter Edition is billed as an entry-level, easy-to-use construction surveying software “at an affordable price point”.

Using a construction GNSS receiver, a supervisor, foreman, grade checker or site engineer can easily check a grade, slope or alignment and navigate the project more accurately and in less time than with traditional survey methods.

Budget-conscious contractors can realize a quick return on investment by giving more personnel on the jobsite access to survey technology, enabling more productive and efficient field crews.

Low-Cost, Scalable Construction Surveying

“The Trimble Siteworks SE Starter Edition is an important addition to our site positioning portfolio,” said Scott Crozier, vice president of Trimble Civil Construction, “With a lower cost-of-entry, the software is scalable and makes it easy for contractors to upgrade to more advanced Trimble Siteworks Positioning Systems as soon as their needs change.”

Read the full Construction Global article.

THINK BIG. START NOW: Trimble Siteworks SE Starter Edition

Trimble Siteworks SE Starter Edition is tailored to users who do not require a full construction-surveyor feature set but offers them access to the same 3D constructible models, GNSS positioning and real-time digital data used by survey crews and machine operators.

Faster decision and improved communications between the field and office are the immediate results.

An upgrade to the standard version is possible anytime.

Read the Trimble News Release about Siteworks SE Starter edition HERE.

Ask us to show you how you can make your team more effective with Siteworks SE starter edition.

Trimble’s Spot the Robot Dog for Site Documentation

The Trimble-branded version of Boston Dynamics’ Spot robot includes a GNSS antenna and a laser scanner, as well as integration into Trimble’s Field Link and Earthworks software applications.

The Trimble-branded Spot will be able to work outdoors on large civil projects. “On the civil side where they are moving dirt around, that’s the primary users of GNSS,” says says Martin Holmgren, Trimble general manager for building field solutions.

Spot will be integrated into Trimble Earthworks, where can be used to track progress on earthmoving jobs.

The Spot robot, with its ability to traverse cluttered jobsites as well as climb and descend stairs, can capture laser scans and location data in a more consistent way than a human surveyor. And since Spot is able to work without direct supervision, it allows for regular scans of jobsites during off-hours. “With Spot, we’ll be able to collect more data, better data, up-to-date data,” explains Holmgren. “That way when the team arrives, the dog can have been out in the morning or the night before, and we have the data already collected for the day’s work.”

Read the full Engineering News-Record Article here.

Not something you see everyday! Only 10 in Australia

Digital Grade Dirt chooses Trimble GCS 900 2D laser for its Laser-Grader

SITECH Solution’s Christo Ferreira recently had the pleasure of installing a Trimble GCS 900 2D laser system onto one of only ten such Laser-Graders in Australia.

Based in East Jindabyne, Digital Grade Dirt’s Laser-Grader is unique around the world. The 1.5t machine is the only miniature grader in manufacture, with the next size being 7t.

A cost effective machine suited for work on driveways and small areas, its design makes it perfect for unique applications – working basement levels, navigating through pillars, gaining tunnel access & getting in underground.

With the GCS 900 grade control installed, Digital Grade Dirt has recently been able to submit a proposal for the Snowy 2.0 project, which is the next chapter in the Snowy Scheme’s history. The project involves linking two existing dams, Tantangara and Talbingo, through 27km of tunnels and building a new underground power station.

The Laser-Grader specialises in precision grading and achieving a fine, flawless material finish, unequalled when coupled with Trimble grade control.

The Trimble GCS900 2D Grade Control System for motor graders is an excellent first investment for contractors new to construction technology looking to improve the efficiency and productivity of their machines.

Connected construction according to Trimble

The connected construction site is gaining in popularity, even if the word “connected” has turned into somewhat of a buzzword.

People, machines, workflows – they have all become connected. In construction this means that we now have direct links between the office and field, between models and machines, software and hardware, platforms and services.

While the efficiency benefits of this connectivity might be more obvious on the higher level of project management, what does it bring to workers executing tasks on a project? Connectivity can help speed up project delivery, raise quality, achieve cost efficiencies, make work safer, and reduce environmental impact of construction projects.

Read the full theconstructionindex.co.uk article to learn more about the constructible process, constructible models and the related:

👉🏻productivity gains

👉🏻greater quality assurance

👉🏻increased safety

👉🏻greater transparency

👉🏻 greater sustainability

that you can achieve by working with Trimble Connected Construction.

Contact us to learn more about Trimble Connected Construction https://bit.ly/3t2Ye36

New Trimble Survey Controller for Land and Construction Surveying

Offering all the benefits of the TS3 controller, The TSC5 is brought up-to-date with an Android operating system, a 5-inch screen and backlit keyboard.

Trimble introduced the Trimble TSC5 Controller for Trimble S series total stations, which is a new rugged, light-weight and compact field solution for land and civil construction surveyors. The Trimble TSC5 features a 5-inch sunlight readable screen with a 13MP rear-facing camera, keypad and all-day battery for field data collection. Its ergonomic design is lightweight (934 grams), easy to grip and made for rugged environments.

The TSC5 is resistant to shock, dust and water while a brightly lit, anti-glare screen and backlit alphanumeric keypad enable fast and efficient operation. The controller’s battery provides all-day power on a single charge and with an optional external battery, the power for extended use is nearly doubled.

The controller supports compatible Trimble GNSS receivers, such as the Trimble R12i and Trimble R12 for high-accuracy positioning requirements. It features a Qualcomm 2.2 GHz processor, 4 GB memory and 64 GB storage, worldwide WWAN with hot spot capability (AT&T and Verizon certified).

Software integration

Featuring an Android 10 operating system, the TSC5 is fully integrated with Trimble’s land and construction surveying instruments and software packages, including Trimble Access 2021 Field Software and Trimble Siteworks Software. Version 2021.00 of the Trimble Access software was released in February 2021, offering new hardware support (such as the newly released Trimble SX12 scanning total station and the TSC5) and multiple product enhancements. In addition, the TS5 controller can be used with Trimble Forensics Capture, Trimble’s data collector software that simplifies scene evidence gathering and enables a seamless transition to Trimble Forensics Reveal desktop software for in-depth analysis.

Add-on functionality

Functionality can be added to the TSC5 with an optional user-replaceable Trimble EMPOWER module, such as a long-range radio or sub-meter GNSS receiver: the EMPOWER Module system includes the ability to add the EM100 (GNSS), EM11X family (RFID/Barcode) and EM120 (Long Range Radio) modules. The Trimble EMPOWER Module system gives users the possibility to customize their mobile computing solution to their own workflow with added scalability.

Read the full spar3D.com article

Trimble and VayaVision Establish Alliance to Make Intelligent Automation Even Smarter

Trimble and VayaVision, a LeddarTech Company, have announced an alliance that will bring advanced perception technology to the agriculture, construction and mining markets.

The integration of VayaVision’s raw data sensor fusion and perception software platform with Trimble’s existing industry-leading machine control technology can enable intelligent automation in complex work environments.

The alliance is focused on advancing data fusion for multi-sensor systems such as LiDAR, cameras and GNSS. These sensors are used to produce reliable environmental mapping, which is critical for autonomous solutions. The result is expected to enable improvements in the performance of autonomous machines operating in challenging work environments or when supporting safety-critical applications.

“Trimble has been connecting the physical and digital worlds with our best-in-class automation technologies for more than 20 years—whether it is in agriculture, construction or mining,” said Finlay Wood, business area director for Trimble’s Autonomous Solutions Division. “We see the demand for operator assistance, autonomous machines and workflow optimization accelerating dramatically and alliances such as this are a critical part of how we will bring added value to our customers in all levels of autonomy.”

Read the full press release HERE.

SITECH Solutions, Supporting You: Trimble GPS base station and Rover set up

Happy Women in Construction Week!

This week, March 4 through 10, the National Association of Women in Construction (NAWIC) is celebrating their annual Women in Construction (WIC) Week.

The construction industry is facing a massive labour shortage. The labour and skill needed to relieve that shortage, however, are readily available. Despite making up a fraction of the current construction workforce, women are poised to move toward the forefront of the industry with a slow, but steady influx of female engineers, architects, project leaders, tradeswomen, contractors, and more.

That’s where NAWIC and events like WIC Week come in.

Stereotypes abound, young women — and perhaps even the general populous — don’t associate the construction industry and women in the way that they should.

WIC Week gives NAWIC members the chance to promote opportunities in construction for women within their communities, thus also generating a conversation around diversity in the trades.

Read the full article on BuiltWorlds.

How Tech Enhances Machine Safety On Site

Augmented reality (AR) platforms such as Trimble Earthworks combine a digital space with the physical worksite. When used with an on-cab camera, operators can see virtual design elements—such as avoidance zones—superimposed over the real site.

“This allows operators to visualize the design in relation to the site,” says Cameron Clark, earthmoving industry director at Trimble. “If they are in the cab of the excavator and they look around or rotate the machine, they can see what they have to build and how it relates to the ground as it stands today.”

With AR, operators are also able to determine the location of underground utilities with respect to their bucket. This provides more spatial knowledge, and shows an operator what the job requires before breaking ground.

“Instead of looking at a digital screen where you’re not sure where things are, you can superimpose these areas through the eyes of the operator using AR,” Clark says. “You can draw those areas through the camera and see exactly where they are on the ground.

“If there’s a conflict in the design, or maybe something is just completely wrong…you have a way to visualize what the final product is. You can bring a lot more confidence.”

Trimble Earthworks also brings greater awareness around the bucket of the excavator.

“If an operator is working in a trench, a lot of the time you’ll see people in the trench laying pipes, and you’ll see excavator operators standing and looking down into the trench,” Clark says. “This is very dangerous because they’ll stand up, look over, sit back down, get up again, and a lot of the time they don’t actually disengage the hydraulics.”

If an operator accidentally bumps a lever in the cab, the boom can swing and potentially hit someone.

“With the camera on the machine you can actually see at a better angle into the trench without having to stand up and look over,” he says. “It provides another angle to see all around, and give greater awareness.”

Read the full Construction Equipment magazine article here

Trimble announces version 5.40 of Trimble Business Center office software to maximise productivity

Trimble announces version 5.40 of Trimble Business Center office software to maximize productivity by streamlining point cloud workflows.

The software will automate and integrate additional data types which will enable increase in accessibility and scalability for survey, mapping, and businesses in engineering.

Tim Lemmon, Marketing Director, Trimble Geospatial Software said, “With the addition of Monitoring and Tunneling modules and the new feature extraction capabilities, customers now have access to powerful new tools that enable them to start and stay in one software.

The new software has automated 3D point cloud extraction which efficiently extract information are critical to maximize productivity.

It also has civil infrastructure and tunneling applications and provides additional data types. It also has new subscription plans to enable businesses to more effectively manage and control their operating expenses.

Lemmon added, “The new subscription plans make Trimble Business Center even more accessible for survey and construction professionals, allowing them to better manage and scale their capabilities as their business grows.”

Article from GeospatialWorld.net.

Ultimate Trim: PUMPED about Trimble v2.0 Earthworks

Matt Browne from Ultimate Trim is PUMPED about the new Trimble Earthworks v2.0 machine control system we fitted to his 140M2 Cat grader.

Ryan Van Arkells and the boys completed the install for Matt and he can’t wait to put it to work.

“The boys have done a fantastic job and I’d like to say thanks,” says Matt.

First project the newly kitted up Cat will be working on is roadworks for the Rail to Western Sydney Airport.

Trimble’s Earthworks Grade Control Platform version 2.0 introduces new features for all machine types, including the Trimble Earthworks Assistant App which provides an easier way to access critical Earthworks learning material and documentation, allowing for a shorter learning curve and less downtime for operators. These improvements are designed to enable faster ROI while increasing productivity and decreasing training time for operators.

ABOUT ULTIMATE TRIM

Ultimate Trim services both NSW and QLD, specialising in final trim including:

Road/railway pavements

Subgrade/all gravels

Detailed finishing works.

Automatically Set Screed Slope and Depth with Trimble’s New Roadworks 3D Paving Control

Contractors ready to ditch the stringline or upgrade from 2D paving have a new option as Trimble launches its Roadworks 3D Paving Control Platform for Asphalt Pavers.

With 3D paving, the operator can pave to the project’s design specifications.

After being fed the design, the system automatically controls the paver’s screed. It can take out high and low areas on the first layer as the screed follows the design for slope and thickness. The system automatically lays the right amount of asphalt for improved accuracy and increased productivity.

By avoiding excess asphalt placement, the system increases road smoothness.

This can also lead to potential bonus pay on projects that offer such incentives. It also means not having to spend time setting out and taking up stringline.

Read the full article in Equipment World.

Introducing Trimble Roadworks 3D Paving Control Platform for Asphalt Pavers

A clear vision with Trimble SiteVision

Engineering and surveying consulting firm Smith Roberts Baldischwiler (SRB) has implemented a new approach to working with landowners affected by energy development.

Instead of 2D paper drawings, SRB uses Trimble SiteVision to provide accurate, on-site visualizations of proposed easements or structures.

Running on an Android-based smartphone, SiteVision uses Trimble Catalyst technology and precise GNSS to determine its position accurate to 1 to 2 centimeters. SiteVision then overlays a 3D model of proposed improvements onto a realtime image of the site.

The handheld system is simple to use and provides an accurate visual depiction for the landman and landowner.

“The ability to visualize the alignments and rights-of-way on the ground is almost priceless. It streamlines the process and you can speed through a project very quickly,” says Taylor Denniston, SRB Director of Survey and Mapping.

Trimble Earthworks for Excavators Grade Control Platform. Finalist for Technological Innovation Of The Year in the Australian Earthmoving Awards.

We’re proud to share that Trimble Earthworks for Excavators Grade Control has been announced as a finalist for Tech Innovation of the Year by Australian Earthmoving Magazine.

The Trimble Earthworks for Excavators Grade Control Platform is designed to help you do more in less time.

Reengineered from the ground up, the innovative, next generation grade control platform features intuitive, easy-to-learn software that runs on an Android operating system. And state-of-the-art software and hardware give operators of all skill levels the ability to work faster and more productively than ever before.

Trimble Earthworks is the first integrated 3D aftermarket grade control with automatics for Excavators and tilt-rotator attachments. Excavators can work semi-automatically, allowing operators to create smooth, flat or sloped surfaces more easily.

Trimble Earthworks can be installed by SITECH Solutions in either 2D or 3D options.

Trimble Earthworks for Excavators Grade Control Platform. Finalist for Technological Innovation Of The Year in the Australian Earthmoving Awards.Read the Australian Earthmoving Magazine article HERE.

2D Trimble GCS900 Grade Control System: excellent first investment for contractors new to construction technology

5 new rover kits – Christmas comes early for WEM!

.

.

Get your free eBook: Drones for Construction

Our friends from Propellor are giving away a Free eBook: Drones for Construction. The Beginner’s Guide.

Trimble Stratus drone technology is powered by Propellor’s Aeropoints. Trimble Stratus helps civil contractors use drones to map, measure and share accurate information about their worksite and assets. With Stratus you can make quicker decisions, avoid mistakes, and grow profits by always having the right information on hand.

With Trimble Stratus you can:

👉🏻 Confidently plan and estimate

👉🏻Calculate site volumes

👉🏻Conduct site checks

Go to Propellor’s website to grab your copy of their free ebook and to learn more Trimble Stratus drone technology contact us today.

Trimble and Boston Dynamics Announce Strategic Alliance to Extend the Use of Autonomous Robots in Construction

The jointly-developed solution will combine the Spot robot’s autonomous mobility with Trimble’s data collection sensors and field control software to enable automation of repetitive tasks such as site scans, surveying and progress monitoring, while taking advantage of the robot’s unique capabilities to navigate dynamic and potentially unsafe environments.

Spot is an agile mobile robot that navigates terrain with unprecedented mobility, allowing you to automate routine inspection tasks and data capture safely, accurately, and frequently.

The results?

Safer, more efficient and more predictable operations.

The Trimble and Boston Dynamics relationship gives Trimble exclusivity to sell and support the Spot robot with integrated scanning, total station and GNSS technologies for the construction market.

“Robots will play a crucial role in automated construction workflows and can augment the human workforce by handling dirty, dull and dangerous tasks,” said Martin Holmgren, general manager, Building Field Solutions at Trimble.

“We’re excited about this alliance and the potential to bring unprecedented improvements in safety, quality and productivity to our construction customers.”

🔗 Read the article in Cision PR Newswire: https://prn.to/35ksqwp

Canberra Contractors presents Trimble SiteVision Part 3

Canberra Contractors Presents Trimble Site Vision. Canberra Contractors have been involved with Trimble SiteVision since day one, being part of Trimble’s beta testing for its development.

This video demonstrates how Trimble SiteVision, pioneering augmented reality solution, makes it possible for you to walk from the construction site into the virtual completed site on-site on one of their Australian Capital Territory (ACT) subdivisions.

You can physically see the scale of all of the hydraulic services that have to be installed on the job and where they sit beneath the ground in relation to the job. Trimble SiteVision enables you to see where everything sits in real time and space; and allows you to check for any clashing services.

With Trimble SiteVision –

📍Take a walk through your job site and visualize:

– Conceptual designs, from buildings to roads, as they might appear in real life

– What lies beneath the ground or resides inside walls, such as water pipes and electrical services

📍Provide real world context to designs:⠀

– Communicate complicated plans and drawings

– Precisely identify where concealed assets are

– Minimize costly errors and safety related incidents

– Simply upload your data, visualize and manipulate it in the field, report back to the office—all through the Trimble Cloud.

ABOUT CANBERRA CONTRACTORS:

Established in 1983, Canberra Contractors has grown from a small local company to a well-established Civil Contractor in the Capital Region.

Canberra Contractors undertakes a full range of construction activities from intricate small-scale projects to large government infrastructure works.

The strengths of the business are founded on highly experienced staff and extensive capability to resource projects.

Canberra Contractors is a forerunner in the development and implementation of new construction methods and innovations.

Known as an industry leader in geospatial technology, with a wide-ranging fleet of machines outfitted with the latest technology, Canberra Contractors is a results driven organisation as evidenced by past and present performance.

Trimble’s drone-based tech for construction

Trimble is offering progress tracking software that combines with drone flights to aid the mapping, measurement and management of construction sites.

The data analytics and visualisation platform, Stratus –powered by worksite analytics software from Propeller – is designed specifically for earthmoving applications.

Using the technology in conjunction with Trimble’s Connected Site solutions, Sitech says contractors need only place and activate ground control points, then undertake drone flights to collect valuable site data, using Stratus to upload and view the data, which can be shared across teams working remotely.

Jan Wouter Kruyt, director of European Operations at Propeller, said, “While other software tries to accommodate a broad category of users, Trimble Stratus is 100% focused on earthmoving and construction environments.”

Kruyt added, “The new package delivers several benefits for construction companies, including capabilities to compare designs and minimise rework by generating highly accurate survey data.

“Most importantly, having frequent up-to-date survey data on hand means that companies can complete projects ahead of schedule and under budget, something that’s becoming more important as companies try to get back on track following lockdown.”

Read the full Construction Europe article HERE.

Continuous improvement policy moves the Baker Group into Trimble machine control

Scott Smith and Brendon Vella were recently onsite in Penrith where they installed Trimble GCS900 with full autos onto a Cat 140M grader, along with Trimble GCS900 machine control onto a Cat D6T dozer for the Baker Group.

Celebrating over 40 years in business, the Baker Group consistently pursues a policy of continuous improvement, aiming for increasingly higher standards in the industry and workplace safety for workers, customers and staff.

Keeping true to this policy, Bakers has moved into Trimble machine control with these installations and SITECH Solutions is very proud to have been a part of the transition.

Trimble machine control provides the ultimate tool for enhancing productivity and performance in any mixed fleet of earthmoving equipment.

With it, operators gain a set of intuitive, interactive controls that improve accuracy and speed for both veteran and newer users alike.

Teams using Trimble Earthworks can exceed productivity expectations across jobs of all types.

The newly fitted machines will be working on the construction of the Nepean Business Park, which is officially underway with site rehabilitation work kicking off.

The rehabilitation works which are taking place on a 47ha former quarry site adjacent to the Sydney International Regatta Centre and the North Penrith employment area is expected to take 18 months to two years to complete before building construction work starts.

The project is expected to cost $613 million and will generate $2 billion in economic activity during construction. Once operational, the Park will generate $295 million in wages and contribute $500 million annually to the Penrith economy.

The business park is set to create more than 18,000 direct and indirect jobs.

How GPS Rovers Improve Construction Project Management

For Construction Pros speaks to Casey Cyrus, business area manager for site positioning systems at Trimble, world-class developer of GPS positioning technologies to discuss how the ability of technology to accurately measure projects with unprecedented speed is offering contractors new ways to monitor progress and maintain quality control.

A rover is a small GPS receiver with data-collecting, and usually transmitting, capability. Their ability to quickly and inexpensively measure and report work in progress offers contractors unprecedented insights into their production.

*Trimble SPS986 with TSC7Trimble’s SPS986 GNSS Smart Antenna can function as either a rover or base station. Rovers are common where machines are using GPS-assisted grade control, but their speed and accuracy in measuring site features makes them valuable even without grade automation on site.

*Trimble SPS986 with T10Rovers can be deployed in various ways, including mounted on vehicles to cover more area faster. Trimble’s T10 tablet collects and views site data using the Windows 10 Enterprise operating system, with fast processing and a 10-in. screen for viewing maps and designs, preparing and sharing progress reports.

The data captured and shared is real-time, and it’s accurate – helping construction companies improve productivity, quality and cost control.

Read the full ForConstructionPros.com article HERE.

Three Keys to Technology Adoption in the Construction Industry

Construction contractors who are hesitant to implement new technologies into their business will fall behind. Want to lead the pack? Start here.

This For Construction Pros article discusses Three Keys to Technology Adoption in the Construction Industry, saying that construction contractors who are hesitant to implement new technologies into their business will fall behind.

The article talks about ways that construction industry organisations can prepare for and can avoid being overwhelmed by the magnitude of new and emerging technologies.

Access the full For Construction Pros article via our website HERE.

Platinum Plant & Haulage Out in Front with Trimble Earthworks.

Australian Earthmoving caught up with Thomas McManaway, Director of Platinum Plant & Haulage, to talk about life, business and his latest addition to Platinum’s growing fleet…a new Kobelco SK350LC-10, which Thomas affectionately refers to as the ‘big girl’ of the fleet.

*The ‘big girl’ of the Platinum fleet – brand new Kobelco SK350LC-10 fitted with Trimble EarthworksThe name Platinum Plant & Haulage reflects the company vision to provide outstanding customer service using state of the art equipment.

“We strive to make sure that we stay at that Platinum status,” Thomas explains. “We stay with quality over quantity; we’re not the biggest earthmoving company out there, but people definitely know who we are – because of the quality of the gear, the operators and, of course, the service.”

*Thomas McManaway, Director of Platinum Plant & HaulageOffering such a broad set of machines (and “just about everything you can think of” in terms of attachments) has meant that Platinum has been involved in a similarly wide range of jobs. “We’ve been a part of almost every type of project we could possibly be on,” says Thomas. “Everything from highway upgrades to housing estates, through to… just everything, really.”

Now with 13 operators on the books, all of Platinum’s machines run Trimble Earthworks, which Thomas rates very highly. “It’s so good physically seeing that image in front of you – because it’s on the iPad now. Seeing that 3D design is so much easier and ensures precision excavation.”

Thomas likes the Trimble system for its ease of use and the many benefits it provides him and his clients. “Basically, the surveyor creates the design of what he wants and gives it to us on a USB flash drive. Then we plug it in and the 3D image is projected right in front of you. That gives you a really good idea of what the map has to look like,” he explains. This, Thomas says, not only makes the whole process quicker but also more precise. “When you’re in a 30-tonner and cutting down to 10mm of tolerances, that’s kind of a big thing!”

Access the full story here or read it in the latest edition of Australian Earthmoving Magazine.

SITECH Management of COVID-19 and Business Continuity Plan

At SITECH Solutions, the health and wellbeing of our people, clients and the community is our highest priority.

We are continuing to closely monitor and manage the evolving Novel Coronavirus (Covid-19) situation.

We are taking every precaution to protect employees and business partners while maintaining our high standards of customer service.

We have specific measures in place to minimise and manage any potential of exposure of our people to Covid-19 whilst undertaking to continue operations and support your business in an uninterrupted manner.

With regards to continuity of supply, SITECH have conducted a full analysis of our current parts inventory. At present we do not anticipate any significant impact on our ability to service your parts requirements specifically related to Covid-19.

READ OUR FULL STATEMENT HERE

Chock-Full of Cool New Features – Trimble Earthworks v2.0 and Earthworks GO!

John Boss and Cameron Clark from Trimble discuss the Earthworks 2.0 machine control platform and its sister product for compact machines Earthworks Go! in this Compact Equipment video.

The Trimble Earthworks 2.0 suite of machine control technologies and modules works on everything from compact track loaders all the way up to big tractor dozers.

It’s chock-full of cool new features, with everything from augmented reality on excavators, horizontal steering on dozers and mastless glade configuration.

Earthworks GO! is specifically designed for compact machine grading attachments, and is taking compact equipment into new applications, reaching new efficiencies never seen before.

SITECH can the system up and running in for you, on any machine, in no time.

Read the full article and watch the video on Compact Equipment.

Letter from The Hon. Dominic Perrottet MP, Treasurer, to the Construction and Engineering Sectors of NSW

A letter from The Hon. Dominic Perrottet MP, the Treasurer of NSW to the construction and engineering sectors of NSW highlights the importance of keeping the sectors working to deliver vital infrastructure programs, the major stimulus package to protect the community, as well as his confidence in the sectors being able to manage the Hazards and Risks of COVID-19.

READ THE FULL LETTER HERE:

NSW Treasurer Dominic Perrottet letter to the construction and engineeri.._[1]

NSW Kick-Starts Economy With $7.5bn Project List

The NSW government has unveiled the first tranche of “shovel-ready” projects it says will kick start the state’s lethargic construction pipeline in the wake of Covid-19.

The 24 projects include Malcolm Turnbull’s pet project Snowy Hydro 2.0—a $4.6 billion injection—along with 4,441 new homes and the $1.5 billion redevelopment of the Mt Druitt CBD.

Read the full The Urban Developer article and see a list of the fast-tracked projects HERE.

Rental Ready at Kangy Angy

SITECH Solutions’ Brendon Vella was recently on site with Civil Movement, small to medium civil project specialist servicing the Central Coast, Newcastle and surrounding area.

Civil Movement were completing works for John Holland on a new rail maintenance facility in Kangy Angy using this Bobcat Track Loader with box blade attachment, fitted with a Trimble GCS900 system and automatic controlled blade.

They hired a Universal Total Station (UTS), a MT900 target and CB460 screen, which allows them to trim with millimetre accuracy.

Regardless of whether you hire or buy, construction technology can be a big investment and a major cost component of any project.

SITECH Solutions provide finance solutions with hire to buy option – a good option to look at to assist with freeing up business cash flow or for those businesses wanting to try before they invest.

We offer:

🏁Latest Trimble technologies

🏁Competitive rates

🏁Superior service

🏁Ongoing support

🏁Flexible terms

🏁Trimble certified training

🏁Installation

For a free consultation and quote, call us on +61 2 6788 2155.

Trimble SiteVision Key to Landing Contracts for Swedish Land Excavation and Construction Company

Trimble recently published a story about Swedish construction company FMT AB’’s experience with SiteVision. One of the things that stood out was the extent to which SiteVision is integrated with the client communication process.

Fredrik Bergstrom, CEO and owner of FMT AB, explains how using augmented reality technology to show clients the deliverable has become integrated into the project.

Fredrik’s forward-thinking implementation of augmented reality for small businesses has led to FMT AB landing contracts that would typically have been awarded to much larger organizations.

Fredrik says that more customers are choosing his company for projects, not because of the price, but because Trimble SiteVision gives them the ability to use 3D modeling to show in the real world exactly what they can deliver for a certain amount of money.

Partnering with Coates Hire to provide Intelligent Compaction

Keeping Your Finger on the Pulse with Trimble SitePulse

Under the Impression That Repeatable Processes Aren’t for Construction? Think Again

With increasingly complex projects and tighter schedules, standardizing processes is a foundational step toward working faster, smarter and with less risk.

The construction industry has made incredible strides in digital transformation. And while technology has been a key driver of this shift, transformation will not be achieved simply by implementing new technologies, but by improving workflows with repeatable business processes.

As the industry moves down the path to digital transformation, repeatable processes are a key element of a constructible process that optimizes the entire design, build and operate life cycle.

Jon Fingland, General Manager, Collaboration Solutions, Trimble Buildings’ General Contractor/Construction explains in this Construction Executive article: https://bit.ly/2VmZBLS

NOW AVAILABLE Trimble Smart Haul for accurate load/haul payload and productivity measurement

Load/haul operations represent real opportunities to improve material moved per shift, lower cost per ton moved and accelerate mass haul operations.

With Trimble Smart Haul, you can track productivity and progress of load/haul operations to ensure you are on target to achieve your goals.

Smart Haul combines payload data from the excavator scale with haul fleet monitoring and cloud reporting to identify opportunities to move material with greater speed and efficiency.

The system is almost completely automated with only minimal interaction from the excavator operator. Payload is automatically assigned to each truck, and GPS tracking monitor truck movements, so operators can focus on other tasks and you can trust data accuracy.

Benefits

Accurate visibility of haul operations

Optimized payload on every truck

Lower and more consistent cycle times

Unscheduled downtime and project delays reduced

Cycles matched to primary crusher demand

Lower idle times

Lower cost per tonne moved

Improved overall production

Improve haul safety with driver alerts and reporting

plus much, more – watch the video for the full details and contact us today to learn more.

Mid-Western Regional Council to Compact Waste Using Less Space with Trimble CCS 900

SITECH Solutions’ Ryan Van Arkkels and Peter Hoy were recently onsite at Mid-Western Regional Council’s waste management facility to fit a Trimble CCS900 cab mounted compaction control system with VisionLink to their TANA E320 landfill compactor.

Mid-Western Regional Council will use the system to track the compaction of the landfill portion of their waste management facility .

The Trimble CCS 900 compaction control system is a landfill solution that enables you to compact more waste using less space.

You can get to target compaction faster, with greater accuracy and less fuel cost; without the added time and expense of stakes and survey crews. It can help you lower operating costs, increase productivity and lengthen the life of the landfill.

Trimble CCS900 delivers real-time guidance, elevation, cut and fill mapping, and compaction information to the cab of the machine, giving operators the information they need to maximize compaction and spreading efficiency, resulting in optimum densities and airspace utilization on the landfill site.

VisionLink reporting takes this data and allows it to be reported on back in the office where it can be used for upcoming planning and quality assurance reporting.

Compact more waste using less space with Trimble machine control systems for dozers, four-drum compactors and motor graders.

Contact us to find out more https://bit.ly/2RA5HGw

Trimble Earthworks for Excavators – Augmented Reality Camera

Trimble Earthworks for Excavators – featuring Augmented Reality Camera. What’s not to love??! 😍

🚩Your real worksite…

🚩Live on display…

🚩Your design topology…

🚩Overlaid on your worksite…

🚩Site conditions clearly in view…

🚩Ultimate guidance…

🚩Just TOO easy…‼️

Contact us today to find out more.

Unleashing the power of survey control with Trimble TSC7

Trimble TSC7 Controller, which is a field solution for land and civil construction surveyors, is in a league of its own. It has a specialized software that makes it easier for mobile workers to collect and compute data.

Designed on customer feedback, TSC7 has some really powerful enhancements. It supports an interactive, user-friendly tablet experience with a physical keyboard and a seven-inch touchscreen. It also has two cameras — front and rear — that provide the option of video conferencing, capturing HD videos and adding an important context.

The Trimble TSC7 is redefining surveying

“Today’s surveyors are managers of geospatial intelligence,” says Ron Bisio, Vice-President, Trimble Geospatial. “Data has more depth and complexity than ever before, and surveyors’ reputation depends on transforming that data into valuable, reliable information for their clients. The TSC7 and Access 2018 form the new backbone of our field solutions ecosystem and give our users a leading edge to be data experts,” Bisio adds.

For civil engineering and construction, along with TSC7, Trimble also has two new rover systems: Trimble Siteworks Positioning System for construction surveyors and the Trimble Siteworks Positioning System for supervisors.

“Siteworks gives customers the ability to work with larger, more complex 3D datasets more effectively in the field,” says Scott Crozier, General Manager, Trimble’s Civil Engineering and Construction Division. “Powerful hardware, intuitive software and the latest advances in site positioning technology from Trimble prepare contractors for the future of 3D construction,” Crozier explains.

Read the full article here https://bit.ly/3ak3B4O in geospatialworld.net

Trimble UTS provides a solution on challenging sites

SITECH Solutions Jye Gregory and Matt Leonard were recently out on WPL Civil’s jobsite – a housing estate development in Macksville, south of Coffs Harbour.

WPL Civil’s Hitachi Zaxis 225US zero tail swing needed to run Trimble 3D Earthworks Grade Control for Excavators with 1.11.0 firmware to allow the use of Trimble UTS.

The Trimble UTS system was required instead of GPS on the excavator on this particular site as they are operating under trees and with very minimal phone service. In such challenging conditions the Trimble UTS Is more accurate whilst GPS struggles with multipath.

“The customer wanted the machine running on UTS due to trees they’re working under,” explains Matt. “It’s fairly easy to set up, however the system must be at 1.10 or 1.11.

Once that’s done the option to switch to single UTS right or left becomes available.”

Providing the highest possible degree of accuracy for construction site positioning, stakeout, measurement and machine control, you can use Trimble UTS for:

⠀⠀

· Smaller construction sites or combined with GNSS on larger sites

· Tasks where the accuracy requirements are very tight: 3 millimeters (0.01 feet)

· Measuring dangerous or inaccessible locations

· High precision machine control and guidance

· Reflectorless measurement of stockpiles, rock faces, cuttings and structures

· Layout of structures, foundations, caissons and piles

· Tunnel measurement

· As-built records and grade checks on laid material

Contact us today for more info https://bit.ly/3aheOn1

About WPL Civil

WPL Civil Pty Ltd is a privately-owned family company based on the Mid North Coast of New South Wales. A civil contracting company who specialise in the construction of small to large community infrastructure projects, WPL Civil expertise includes road construction, subdivision construction,, bulk earthworks, drainage installation, concrete pavement, kerb and gutter, landscaping, clearing and grubbing, water/ sewerage reticulation and plant hire.

D&M Excavating Completes Site Work with One Machine Instead of Two Using Trimble Earthworks Grade Control Platform

Site contractor uses Trimble Earthworks for Montgomery County Fairgrounds site work, reducing dozer use significantly, cutting operating costs and getting to grade faster

Overview

Customer Profile: Located outside of Dayton, Ohio, D&M Excavating delivers excavation and site development work for commercial and residential customers. Site work includes mass excavation, site grading and finish grading. From road construction projects to multi-family and plat developments, D&M Excavating is committed to site development excellence and premium customer service.

Business Challenge

D&M Excavating was looking to improve its excavation and grading productivity and machine utilization to reduce costs and complete jobs more quickly.

Solution

Trimble GCS900 Grade Control System and Trimble Earthworks Grade Control Platform

Benefits:

Cut dozer use significantly– Reduced reliance on dozer on fairgrounds project, significantly reducing fuel costs, cutting machine wear and tear and freeing up the dozer for other tasks and projects

Significant productivity gains during mass excavation and fine grading– With a 3D view of the project and grade progress inside the cab, operator doesn’t have to rely on stakes or grade checker to dig to correct depths

Demonstrates competitive advantage– Reaching grade more quickly and with less rework keeps projects moving forward and on schedule, which is appealing to general contractors and owners

Potential for big savings for pipe work– D&M purchased Trimble Earthworks Grade Control Platform for its new excavator for pipe work for greater grading productivity at a lower cost

🚩🚩Coronavirus Budget Stimulus

The Government is backing businesses to invest to help the economy withstand & recover from the economic impact of Coronavirus. The 2 business investment measures in this package are to assist Australian businesses and economic growth in the short-term, & encourage a stronger economic recovery following the Coronavirus outbreak.

These measures will support over 3.5 million businesses (over 99 per cent of businesses) with aggregated annual turnover of less than $500 million employing more than 9.7 million employees.

📍INCREASING THE INSTANT ASSET WRITE-OFF

-Summary

The Government is increasing the instant asset write-off (IAWO) threshold from $30,000 to $150,000 & expanding access to include all businesses with aggregated annual turnover of less than $500 million (up from $50 million) until 30 June 2020.

-The IAWO threshold

The higher IAWO threshold provides cash flow benefits for businesses that will be able to immediately deduct purchases of eligible assets each costing less than $150,000. The threshold applies on a per asset basis, so eligible businesses can immediately write-off multiple assets.

The IAWO is due to revert to $1,000 for small businesses (turnover less than $10 million) from 1 July 2020.

-Eligibility

The annual turnover threshold for businesses is increasing from $50 million to $500 million.

📍BACKING BUSINESS INVESTMENT (BBI)

-Summary

A time limited 15 month investment incentive to support business investment & economic growth, by accelerating depreciation deductions.

-Key features:

benefit — deduction of 50% of the cost of an eligible asset on installation, with existing depreciation rules applying to the balance of the asset’s cost;

eligible businesses —aggregated turnover below $500 million; &

eligible assets — new assets that can be depreciated under Division 40 of the Income Tax Assessment Act 1997 (i.e. plant, equipment & specified intangible assets, such as patents) acquired after announcement & first used or installed by 30 June 2021.

-Eligibility

Businesses with aggregated turnover below $500 million, purchasing certain new depreciable assets.

FOR MORE INFO VISIT: treasury.gov.au/coronavirus

Trimble Takes Construction Machine Control to the Next Level

Groundbreaking New Features and Industry-Firsts in Trimble Earthworks Grade Control Platform Version 2.0

Trimble announced today Trimble® Earthworks Grade Control Platform version 2.0 with groundbreaking new features for all machine types, along with the release of the Trimble Earthworks Assistant App for in-cab learning material. These improvements are designed to enable faster ROI, increase productivity and decrease training time for operators.

A first in the construction industry, Horizontal Steering Control for dozers automatically controls the machine to follow any horizontal alignment such as a back of a curb, breakline, roadway centerline or bottom of slope, without operator assistance.

Another first, Augmented Reality for excavators enables users to easily understand 3D models, cut/fill information, slope data and other bench points and reference points on the in-cab display in context, without the need to interpret complex 2D plans or stakes.

A new mastless motor grader configuration gives operators an improved range of blade motion, allowing for machine control in applications where it was previously not possible.

Integrated Trimble LOADRITE® Payload Management displays grade control and accurate payload data on one screen, increasing mass haul productivity and efficiency by preventing underloading, and improving safety by avoiding overloading. Contractors can maximize their investment in Trimble Earthworks by leveraging the versatility of these added options.

Trimble Earthworks is also now available for compact grading attachments with dual GNSS, single GNSS and total station guidance options.