Optimise Production and Revenue of Your Drilling, Piling and Compaction with Trimble Groundworks

Trimble Groundworks Machine Control System can enhance on-site safety, accuracy and the efficiency of your drilling and piling operations. All day, every day, in any weather.

Realise maximum production and revenue with the Trimble Groundworks Machine Control System—an aftermarket, land-based, 3D drilling and piling system for the mixed fleet operator.

Key features include:

- Stakeless drilling or piling and minimal layout to reduce workload and cost

- Enhanced safety by reducing personnel near machines and warning operators when entering avoidance zones

- Reduced operator fatigue by minimising paperwork

Groundworks Applications

- Drilling

- Piling

- Solar farm construction

- Blast hole drilling

- Structural piling

- Wick drain installation

- Continuous flight augering (CFA)/auger cast piling

- Anchor/monopile drilling

- Dynamic compaction

Key Benefits

- Stakeless navigation and minimal lay out reduces workload, rework and errors

- Improve site safety by reducing personnel near machines and using avoidance zone alerts

- Auto Stop drills only to the defined elevation

- 2D workflow keep you working even during GNSS signal loss

- In-field drill plan and quality/production reports

- Very high accuracy and precision using RTK positioning

- Navigate to inclined or vertical holes from any direction

- Logging as-built data during operation

Key Features

Key features include:

- Stakeless drilling or piling and minimal layout to reduce workload and cost

- Enhanced safety by reducing personnel near machines and warning operators when entering avoidance zones

- Reduced operator fatigue by minimising paperwork

Trimble Verso Display

Keep your machines working. Not waiting.

Your machines can be up and running 24/7 with the rugged and fully connected Trimble VERSO 12 and Trimble Groundworks. The easy-to read touchscreen makes navigation simple and quick.

- Rugged VERSO 12 display

- Clearly see avoidance zones for safer sites

- Configurable views

- Easy-to-use, intuitive interface

- Modern colourful graphics

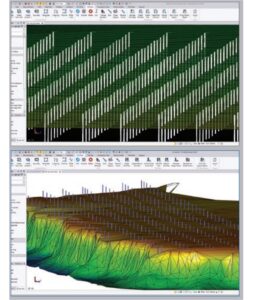

Trimble Business Center for Groundworks

Optimised drill plans. Optimal Results.

Rapidly create optimised 3D drill or pile plans with Trimble Business Center software, then generate comprehensive quality and production reports. With Trimble Business Center and Trimble Groundworks, more profits are at your fingertips.

Trimble Connected Site: Office-to-Field Integration

Trimble Groundworks, an Integrated Solution for Your Connected Site

Part of the Trimble Connected Site portfolio, Groundworks is an integrated solution that brings the office and the field together to give you less rework, more productivity, and best of all—more profitability.

- Trimble Business Center creates and manages design data to avoid costly mistakes

- Connected Community allows design data to be shared in the cloud and ensures operators are always working with the most recent information

- Groundworks gathers as-built data so Trimble Business Center can run accurate quality, production, and utilisation reports

- Trimble WorksManager Software makes it easy to manage up-to-date connected design data and track all of your fleet assets across multiple project sites.

Trimble Groundworks Solutions

The Trimble Groundworks Machine Control System offers unmatched accuracy and efficiency for drilling and piling projects. Reduce rework, enhance safety with avoidance zone alerts, and benefit from real-time data to keep your operations running smoothly.

Trimble WorksManager

Trimble WorksManager is the mobile-friendly software that easily manages data and technology assets across project sites. Trimble WorksManager Software allows users to wirelessly transfer data such as 3D designs to the construction site, increasing …

Software Solutions

Discover Trimble Software Solutions designed for civil construction projects. Increase efficiency, reduce downtime, and stay connected with tools like Trimble WorksOS, WorksManager, and Stratus.

Trimble Earthworks Assistant App

The Trimble Earthworks Assistant App is designed to deliver user assistance information to operators in the field, at the office, or at home.

DPS900 Piling and Drilling

Integrates With

Trimble WorksManager

Trimble WorksManager is the mobile-friendly software that easily manages data and technology assets across project sites. Trimble WorksManager Software allows users to wirelessly transfer data such as 3D designs to the construction site, increasing …

Software Solutions

Discover Trimble Software Solutions designed for civil construction projects. Increase efficiency, reduce downtime, and stay connected with tools like Trimble WorksOS, WorksManager, and Stratus.

Trimble Earthworks Assistant App

The Trimble Earthworks Assistant App is designed to deliver user assistance information to operators in the field, at the office, or at home.

Related Trimble Solutions

Paving Control Systems

From asphalt to concrete, we've got you covered. Pave the way to more profits with paving control solutions from Trimble.

Site Positioning Systems

Tough, accurate, and connected Trimble site positioning systems that deliver precision - reliable and accurate results from the field to your office, no matter the distance.